Base Unit

- hidet77

- Jan 29

- 3 min read

One key point to improving efficiency is defining the base unit.

The base unit is defined as the following in the Merriam-Webster Dictionary;

one of a set of fundamental units in a system of measurement that is based on a natural phenomenon or established standard and from which other units may be derived

“base unit." Merriam-Webster.com. 2025. https://www.merriam-webster.com (28 January 2025).

In operations, I observe two types.

One is the definition of the quantity. In other words, what does “one” mean to the organization. For example, “car” is relatively simple. We buy one car, and the business produces one car. Some entities purchase vehicles in bulk. Yet, their orders are integer multiples of one car. You won’t find anyone who wants 0.3 of a vehicle. In other industries, this might not be so simple. One is not clearly defined. The one might be different between the end customer and the middle entities. Things will be easy if there are integer-multiple relationships between these orders. Unfortunately, typically, there is no logic other than how things were ordered historically.

Another type is the difference in units. Are we selling by pieces, weights, or lengths? If there are some relationships between these units, that is wonderful. However, we typically operate without any rules. On top of chaotic conditions, the profitability adds complexity. If volume is prioritized, smaller pieces with higher margins might be ignored. When margins are prioritized, you might sacrifice the large customer.

When this “Base unit” enters production, the situation gets worse. Why? This is because, typically, each process has the freedom to decide the “units.”

Regarding volume, production decided on the batch size without considering the customer. Here, one batch is typically calculated based on the machine's capacity. When we ask one production batch equals how many customer-ordering units, we won't get a good answer. This is because production wants to protect itself from another problem: performance on yield or quality.

Another problem is that production invents new “units.” When the process is designed, we devise convenient methods. Each method generates a new “word” or “unit.” “We need to hook these parts onto this hanger.” (The hanger becomes the production unit.) “This process processes based on this basket.” (The basket becomes the production unit.) And if this production unit has some integer-multiple relationship, it is somewhat acceptable. But very often, there are no relationships.

Adding to the problems caused by production are the transportation units.

Transportation repeats the mistake of deciding base units randomly. A classic example is a pallet that doesn’t fit into a truck.

When designing a flow, it is crucial to consider the base unit. The benefits are everywhere in the flow.

Flow without a “base unit” will have the problem of fractions. These fractions are turbulences of a flow. These turbulences will cause some trouble to the flow.

Having a good base unit in a flow will make planning easier. A common problem in flow without a base unit is complicated planning, which can become tricky and create opportunities for mistakes. This fear of errors tends to lead to overproduction. Once the relationship between some of the production and transportation units is understood, we often find opportunities to eliminate overproduction.

Another opportunity is to understand the flow's actual yield or quality. When the base unit is not clearly defined, some conversion is created. This calculation allows some allowance to come in. Even with no bad intentions, we will place some numbers on the “safe” side. This hides some problems. Even if that ratio is small, if we think about the total volume and frequency of these conversions happening, it becomes a significant problem.

Many organizations rush to calculate the “takt time” without defining the “base unit.” We must approach them cautiously if different processes can use different base units. At least, different base units need to explain their relationship with the customer base unit. Otherwise, the process is “pushing” in a different way.

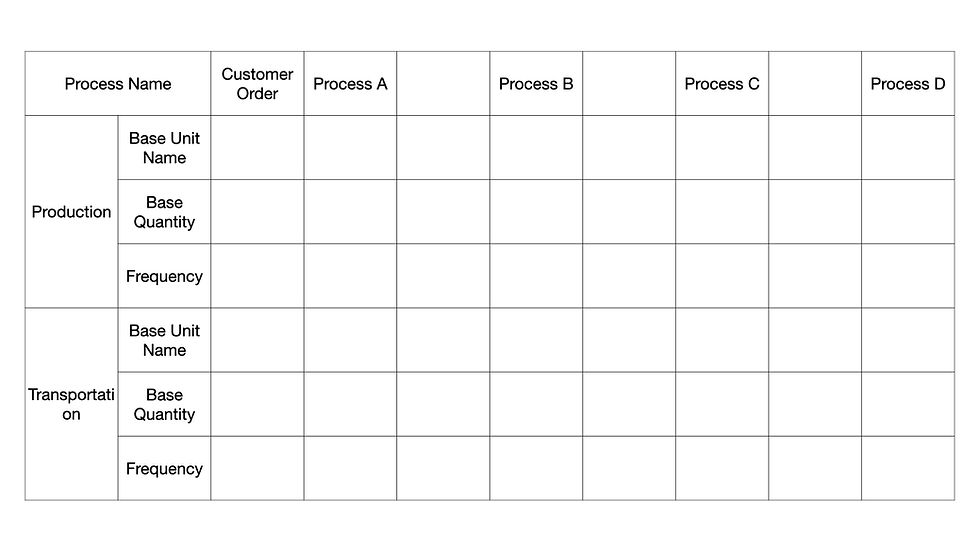

When designing a flow, please consider the base unit. Create a simple table of customer and process base units, and create integer-multiple relationships between them. This is necessary to create a good flow.

Comments